Uncategorized

Waste Anesthetic Gas Disposal (WAGD) Inlet Requirements

June 01, 2022/0 Comments/in Uncategorized / by Cary DardenWaste anesthetic gas disposal is used in healthcare facilities to evacuate rogue anesthesia gases during procedures on patient undergoing anesthesia. This protects both the staff and patient from a potentially dangerous build of these gases in a space like an operating room. NFPA 99 defines it in Chapter 3 (2018 edition ref. 3.3.181) as: “The process of capturing and carrying away gases vented from the patient breathing circuit during the normal operation of gas anesthesia or analgesia equipment.” WAGD may also go by the acronym “AGSS” (anesthetic gas scavenging system) and inlets installed in an OR may be labeled “evacuation” if they were installed prior to the year 2000 or so.

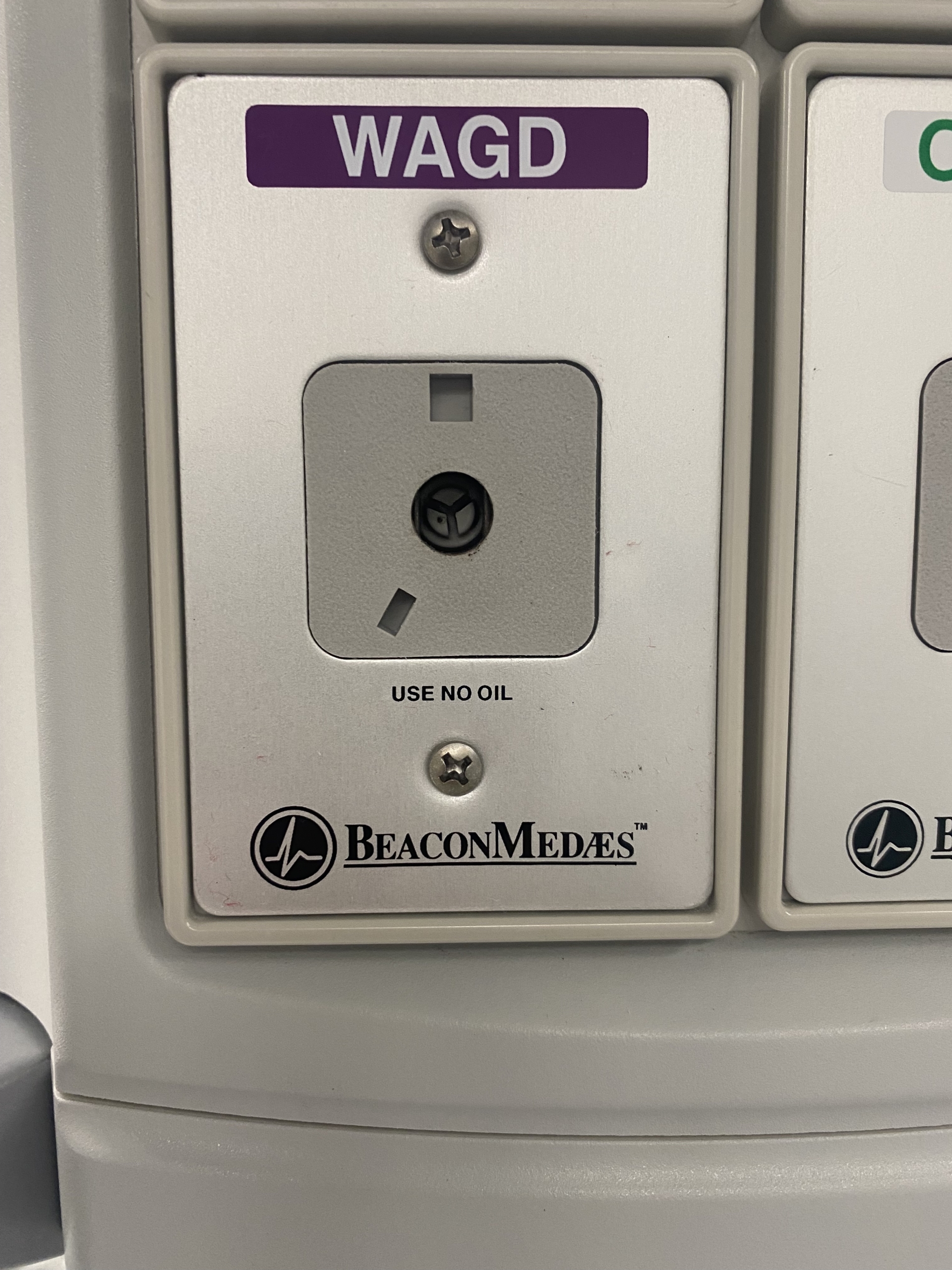

WAGD inlets are required to be labeled / colored differently from medical vacuum inlets (see table 5.1.11 in NFPA 99) and also to be keyed differently so that fittings and devices may not be interchanged between the WAGD and medical vacuum systems.

When or where is a facility required to have a dedicated WAGD inlet?

As part of the 2005 edition, NFPA 99 revised the wording to read that a facility must have a dedicated WAGD inlet in “…all locations where nitrous oxide OR halogenated anesthetic gas is intended to be administered” – NFPA 99 – 2018 ed. ref. 5.1.5.16. NOTE: this reference has remained the same in all subsequent editions as of this writing (2005, 2012, 2015, 2018 & 2021). It should be noted that if a facility has locations where they occasionally anesthetize patients (e.g. CT Scan, X-Ray etc.) by rolling an anesthesia machine into the room, a dedicated WAGD inlet should be provided. Remember however that if you add a WAGD inlet, the room or space is now an anesthetizing area which means it needs a dedicated zone valve (NFPA 99 2018 edition ref. 5.1.4.6.2) and very likely will need an area alarm depending on the level of sedation being administered.

Outlet keying styles (Ohmeda / Medaes quick connect style pictured)

The requirement to have a dedicated WAGD inlet that is keyed separately from medical vacuum inlets was first introduced in the 1996 edition of NFPA 99. Prior editions of NFPA 99 only required WAGD inlets to be keyed differently when they were part of a separate source (such as a dedicated WAGD central supply system) other than the medical vacuum system. The two pictures below demonstrate inlets manufactured under the different requirements from the various edition of NFPA 99. The picture on the left (evacuation – white) has the same keying style as medical vacuum, while the picture on the right (WAGD – purple) has a keying style specific to WAGD only. The inlets in these pictures are utilizing the Ohmeda / Medaes style quick connect style, there are similar examples for Puritan Bennett quick connect, Chemetron quick connect and DISS (Diameter Index Safety System) style.

Old style waste anesthetic gas disposal inlet labeled “Evacuation” and keyed the same as medical vacuum |  Current style waste anesthetic gas disposal inlet labeled “WAGD” with unique keying so as to not be interchangeable with medical vacuum |

Installation of WAGD inlets – “the 5 ft. rule”

Another item that was added within the 2005 edition of NFPA 99 was for dedicated WAGD inlets that were joined to the medical surgical vacuum system (Med Vac / WAGD combined use system) to be connected a minimum of 5 ft from any medical vacuum inlet. When the clinical staff is operating on a patient there are instances when the waste collection canister fills up and the vacuum waste gets into the pipeline. There had been reports that this would not only occlude or block off the vacuum inlet but it would also occlude the WAGD inlet when it was tied into the piping directly next to the vacuum inlet. The 5 ft rule is there to help prevent the loss of the WAGD circuit in an OR due to a blocked vacuum inlet to ensure the continued safety of the staff and patient during the procedure.

Prohibited uses for WAGD inlets

It is worth noting that WAGD (and medical vacuum for that matter) are not to be used for “non-medical applications” – NFPA 99 2018 edition ref. 5.1.14.1.4. The body of that paragraph lists vacuum steam condensate return as an example, but there is an associated reference in the annex (ref. A5.1.14.1.4) that gives more guidance on this reference. That annex reference adds the following items as prohibited uses for medical vacuum and WAGD:

- Scope cleaning

- Decontamination

- Laser plume

Keep in mind that the annex of NFPA 99 is for information purposes only and it not enforceable, having said that an AHJ can enforce the code how they see fit so it is best to abide by the material in the annex when possible.

Medical Gas Emergency Response

November 08, 2019/0 Comments/in Uncategorized / by Cary DardenFailure of critical medical gas and vacuum systems definitely leads to a stressful situation. For this reason medical gas and vacuum equipment must be is redundant to prevent a catastrophic failure to the patient care environment. However, there are always situations where the redundancy may not be sufficient. Recently, we had a situation where a facility had a quadruplex medical vacuum system that needed 2 of its 4 pumps to maintain a sufficient vacuum. One of the 4 pumps had been down for over a month waiting on repairs by another medical gas company. During that time the system experienced another failure and lost another vacuum pump. So now the facility was left with no reserve being forced to run the remaining two pumps non-stop to maintain proper medical vacuum. So what caused this to happen?

The failed check valve in the picture below caused the most recent failure. The oil was pulled out of the pump causing the pump to run hot and “cook” the remaining oil.

Due to the lengthy time of repairs by the other medical gas company, EMGS was called to help resolve the situation. The call was received about 3pm one afternoon and by 6:00 am on the following day a temporary vacuum rental unit was installed at the facility. The facility was now back to 4 working pumps, less than 24 hours later. EMGS has several rental medical air, vacuum and gas manifold systems to meet customer demands during emergencies or planned outages.

EMGS Hosts Medical Gas Expo

April 10, 2013/0 Comments/in Uncategorized / by Cary DardenOur 2013 Medical Gas Expo & Educational Seminar was a huge success! It was held at the AmericasMart in Atlanta, GA on March 21st. Over 40 hospital personnel, engineers, and other medical industry professionals were in attendance.

President and CEO of EMGS, Tot Darden presented on the 2012 edition NFPA 99 code changes.

Guest speaker Jaime Valdivia with NITC spoke on the ASSE credentialing standards. Jaime has 29 years of experience as a craftsman of the plumbing and pipefitting industry. He has held a medical gas installer credential since 1987 by completing a four year apprenticeship program. Jaime holds certifications as a Journeyman plumber, Journeyman pipefitter, Master Plumber, Foreman, and for Green Awareness and also possesses a Los Angeles City Plumber license. Jaime is a graduate of the United Associations Instructor Training Program and he is former instructor of the Apprentice and Journeyman program in Southern California. He earned an Associate in Applied Science as an Honors graduate in the field of Industrial Training and acquired a Bachelors of Arts in Labor Education from the National Labor College.

Matt Nimershiem with Lokring shared his expertise on Lokring fittings in medical gas systems. Matt has been with Lokring for 20 years, and is considered by the company to be their medical gas specialist. Matt has been involved with the medical gas industry since the introduction of the product to the NFPA 99 committee and was instrumental in the usage of Lokring at the recently completed Walter Reed Military Medical Center project in Bethesda, MD. Matt holds a Mechanical Engineering degree from Virginia Tech and is a member of ASHE, ASME, and ASNE.

Joseph Messina, Plumbing Section Manager for HDR Architecture, was another guest speaker. He spoke on Chapter 8 of NFPA 99. He has more than 35 years of engineering experience, in the design and engineering of plumbing systems with an expertise in research facilities, hospitals, detention facilities and civic. Joseph is very active in the Atlanta Chapter of ASPE, serves as VP of Education on the chapter board, and is on the ASPE Educational Committee. He has also authored the Designers Notebook column in the Plumbing System and Design Magazine.

With 25 years of experience with the design, marketing and services of air compressor and vacuum pump systems for medical, research, and industrial facilities Don Goggans with Powerex was able to conclude our forum with his knowledge on source equipment for labs & hospitals. Don has been a member or speaker of Medical Gas Professional Healthcare Organization, American Society of Plumbing Engineers, and American Society of Healthcare Engineers.

We are very appreciative that all of these well-informed men got to share their invaluable ingenuity, and be a part in our educational forum.

Please make plans to join us for future educational seminars. Contact Terri Clayton for further information at 770-459-5920.