Waste Anesthetic Gas Disposal (WAGD) Inlet Requirements

June 01, 2022/0 Comments/in Uncategorized / by Cary DardenWaste anesthetic gas disposal is used in healthcare facilities to evacuate rogue anesthesia gases during procedures on patient undergoing anesthesia. This protects both the staff and patient from a potentially dangerous build of these gases in a space like an operating room. NFPA 99 defines it in Chapter 3 (2018 edition ref. 3.3.181) as: “The process of capturing and carrying away gases vented from the patient breathing circuit during the normal operation of gas anesthesia or analgesia equipment.” WAGD may also go by the acronym “AGSS” (anesthetic gas scavenging system) and inlets installed in an OR may be labeled “evacuation” if they were installed prior to the year 2000 or so.

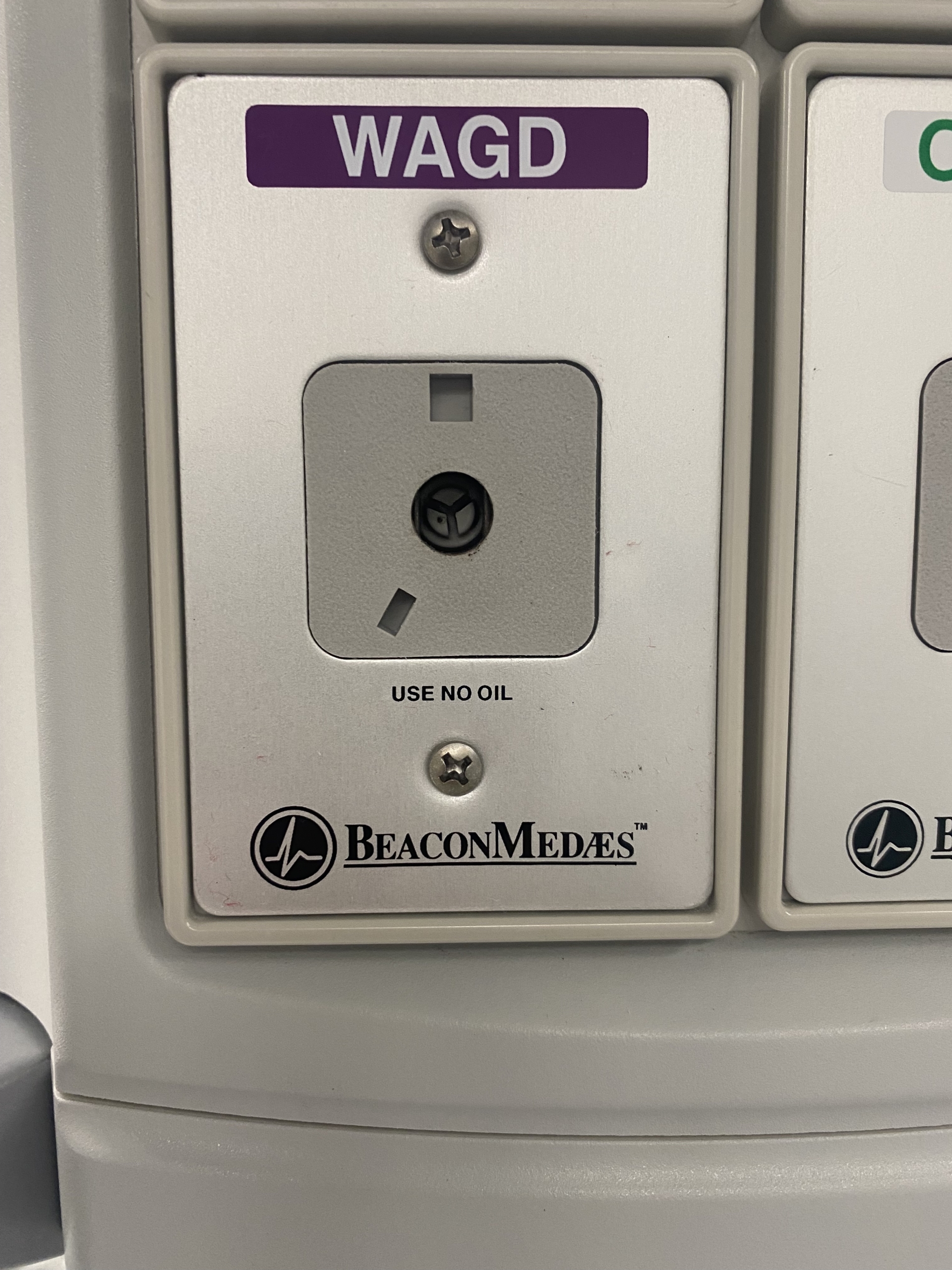

WAGD inlets are required to be labeled / colored differently from medical vacuum inlets (see table 5.1.11 in NFPA 99) and also to be keyed differently so that fittings and devices may not be interchanged between the WAGD and medical vacuum systems.

When or where is a facility required to have a dedicated WAGD inlet?

As part of the 2005 edition, NFPA 99 revised the wording to read that a facility must have a dedicated WAGD inlet in “…all locations where nitrous oxide OR halogenated anesthetic gas is intended to be administered” – NFPA 99 – 2018 ed. ref. 5.1.5.16. NOTE: this reference has remained the same in all subsequent editions as of this writing (2005, 2012, 2015, 2018 & 2021). It should be noted that if a facility has locations where they occasionally anesthetize patients (e.g. CT Scan, X-Ray etc.) by rolling an anesthesia machine into the room, a dedicated WAGD inlet should be provided. Remember however that if you add a WAGD inlet, the room or space is now an anesthetizing area which means it needs a dedicated zone valve (NFPA 99 2018 edition ref. 5.1.4.6.2) and very likely will need an area alarm depending on the level of sedation being administered.

Outlet keying styles (Ohmeda / Medaes quick connect style pictured)

The requirement to have a dedicated WAGD inlet that is keyed separately from medical vacuum inlets was first introduced in the 1996 edition of NFPA 99. Prior editions of NFPA 99 only required WAGD inlets to be keyed differently when they were part of a separate source (such as a dedicated WAGD central supply system) other than the medical vacuum system. The two pictures below demonstrate inlets manufactured under the different requirements from the various edition of NFPA 99. The picture on the left (evacuation – white) has the same keying style as medical vacuum, while the picture on the right (WAGD – purple) has a keying style specific to WAGD only. The inlets in these pictures are utilizing the Ohmeda / Medaes style quick connect style, there are similar examples for Puritan Bennett quick connect, Chemetron quick connect and DISS (Diameter Index Safety System) style.

Old style waste anesthetic gas disposal inlet labeled “Evacuation” and keyed the same as medical vacuum |  Current style waste anesthetic gas disposal inlet labeled “WAGD” with unique keying so as to not be interchangeable with medical vacuum |

Installation of WAGD inlets – “the 5 ft. rule”

Another item that was added within the 2005 edition of NFPA 99 was for dedicated WAGD inlets that were joined to the medical surgical vacuum system (Med Vac / WAGD combined use system) to be connected a minimum of 5 ft from any medical vacuum inlet. When the clinical staff is operating on a patient there are instances when the waste collection canister fills up and the vacuum waste gets into the pipeline. There had been reports that this would not only occlude or block off the vacuum inlet but it would also occlude the WAGD inlet when it was tied into the piping directly next to the vacuum inlet. The 5 ft rule is there to help prevent the loss of the WAGD circuit in an OR due to a blocked vacuum inlet to ensure the continued safety of the staff and patient during the procedure.

Prohibited uses for WAGD inlets

It is worth noting that WAGD (and medical vacuum for that matter) are not to be used for “non-medical applications” – NFPA 99 2018 edition ref. 5.1.14.1.4. The body of that paragraph lists vacuum steam condensate return as an example, but there is an associated reference in the annex (ref. A5.1.14.1.4) that gives more guidance on this reference. That annex reference adds the following items as prohibited uses for medical vacuum and WAGD:

- Scope cleaning

- Decontamination

- Laser plume

Keep in mind that the annex of NFPA 99 is for information purposes only and it not enforceable, having said that an AHJ can enforce the code how they see fit so it is best to abide by the material in the annex when possible.

NFPA 99 2012 Medical Gas Outlet Testing Requirements - Existing Facilities

November 17, 2021/0 Comments/in Compliance Medical Gas Testing / by Cary DardenNOTE: All references are taken from NFPA 99 – 2012 edition, this is an update from the original post which was made on September 3rd, 2015

There seems to be much confusion over the requirements set out by NFPA 99 for existing facilities vs. those for new construction / renovation work. The 2012 edition of NFPA 99 has done a great deal to help bring more clarity to this issue.

5.1.1.5 Subsection 5.1.2 through 5.1.12.3.14.5 and 5.1.14.4.2

shall apply to new health care facilities or facilities making

changes that alter the piping.

5.1.1.6 Paragraph 5.1.14.4.3 through 5.1.14.4.9 and 5.1.13

through 5.1.15 shall apply to existing health care facilities.

NOTE: TIA 12-4 from NFPA 99 – 2012 edition changed the wording from 5.1.1.6 and gave (10) paragraphs that apply to existing healthcare facilities. These are listed below:

5.1.1.6 The following subsections of this chapter shall apply to the operation, management, and maintenance of Category 1 medical gas and vacuum systems in existing facilities:

(1) 5.1.2

(2) 5.1.3.1

(3) 5.1.3.2

(4) 5.1.3.3.1.7

(5) 5.1.3.3.1.8

(6) 5.1.3.3.4

(7) 5.1.3.6.2

(8) 5.1.3.8.5.2

(9) 5.1.14

(10) 5.1.15

NFPA 99 doesn’t mention a specific schedule for medical gas outlet testing on existing outlets, it just says periodic. The healthcare facility will need to make a policy that says how often the med gas outlets get checked (i.e. every three years etc) and adhere to that.

The section of NFPA 99 that specifies all outlets / inlets must be checked falls under the new construction / renovation portion. (5.1.5* Station Outlets/Inlets & 5.1.12.3 System Verification) These requirements as they are written in 5.1.5 & 5.1.12.3 are not intended to be applied to existing healthcare facilities.

The medical gas outlet testing section for 5.1.14 is as follows:

5.1.14.2 Maintenance of Medical Gas, Vacuum, WAGD, and

Medical Support Gas Systems.

5.1.14.2.1* General. Health care facilities with installed medical

gas, vacuum,WAGD, or medical support gas systems, or combinations

thereof, shall develop and document periodic maintenance

programs for these systems and their subcomponents as appropriate

to the equipment installed.

5.1.14.2.3.1 General. The elements in 5.1.14.2.2.2 through

5.1.15 shall be inspected or tested as part of the maintenance

program as follows:

(11)*Station outlets/inlets, as follows:

(a) Flow

(b) Labeling

(c) Latching/delatching

(d) Leaks

Remember that the * next to (11) refers to additional material which is located in the annex of NFPA 99. In this case A.5.1.14.2.3.1(11) simply states that the outlets should be inspected for a general condition & be gas specific (noninterchangeable indexing).

Annex material is not enforceable as code and is meant for reference only however, that doesn’t mean that an AHJ (Authority Having Jurisdiction) will not use annex material for a given facility or situation. Just be aware of the additional requirements located in the annex for this section and take them into consideration when doing your risk assessments and writing your medical gas outlet testing policy.

Calibration of CO (Carbon Monoxide) Monitors for Medical Air Systems

October 28, 2020/0 Comments/in Medical Gas Testing Service / by Cary DardenCalibration of CO (Carbon Monoxide) Monitors for Medical Air Systems

If you’re a healthcare facility with a medical air compressor system, then you have a carbon monoxide or CO monitor on that system. NFPA 99 requires that the CO monitor be calibrated at least annually or more often if recommended by the manufacturer (NFPA 99 2012 ed. 5.1.14.4.7(2) or 2018 ed. 5.1.14.5.7(2)). The “gotcha” moment here is with the second part of that statement regarding the manufacturer’s recommendations. The chart below lists some of the manufacturers recommendations for CO monitors commonly used on medical air compressor systems. As you will see, every single one of them require calibration more often than the annual frequency mentioned in NFPA 99.

| MANUFACTURER: | MODEL: | FREQUENCY OF CALIBRATION PER O&M: | CAL GAS REQUIRED: |

|---|---|---|---|

| Amico / KWJ | A310 / A316 | Every 3 months | 100 PPM |

| Enmet | CO-Guard | Every 3 months | 20 PPM |

| Enmet | MedAir 2200 | Every 3 months | 20 PPM |

| Enmet | ISA-RAL-M | Every 3 months | 20 PPM |

| GFG | ABL-50 / RAM-50 | Every month | 20 PPM |

| GFG | ABL-4021 / RAM-4021 / 4021-DPX | Every month | 20 PPM |

| GFG | 4035 / 4035-22 | Every month | 20 PPM |

Be sure to identify what type of CO monitor each of your medical air systems has on it and take steps to ensure you have documentation showing you are calibrating the monitor(s) per the manufacturer’s recommendations. Keep in mind, if you have multiple medical air systems, you might have different monitors on those systems and they may have different calibration schedules.

Medical Gas Emergency Response

November 08, 2019/0 Comments/in Uncategorized / by Cary DardenFailure of critical medical gas and vacuum systems definitely leads to a stressful situation. For this reason medical gas and vacuum equipment must be is redundant to prevent a catastrophic failure to the patient care environment. However, there are always situations where the redundancy may not be sufficient. Recently, we had a situation where a facility had a quadruplex medical vacuum system that needed 2 of its 4 pumps to maintain a sufficient vacuum. One of the 4 pumps had been down for over a month waiting on repairs by another medical gas company. During that time the system experienced another failure and lost another vacuum pump. So now the facility was left with no reserve being forced to run the remaining two pumps non-stop to maintain proper medical vacuum. So what caused this to happen?

The failed check valve in the picture below caused the most recent failure. The oil was pulled out of the pump causing the pump to run hot and “cook” the remaining oil.

Due to the lengthy time of repairs by the other medical gas company, EMGS was called to help resolve the situation. The call was received about 3pm one afternoon and by 6:00 am on the following day a temporary vacuum rental unit was installed at the facility. The facility was now back to 4 working pumps, less than 24 hours later. EMGS has several rental medical air, vacuum and gas manifold systems to meet customer demands during emergencies or planned outages.

Medical Gas Backfeed

March 15, 2018/0 Comments/in Medical Gas Testing Service / by Cary DardenMedical air is one of the most crucial medical gases serving an NFPA 99 Category 1 facility or space. It is typically responsible for keeping ventilators and blenders running and downtime of any length is simply not acceptable.

When work must be performed on the air compressor source, especially within the control panel, power may have to be disrupted to safely complete that job. One way that EMGS helps ensure that the medical air supply remains uninterrupted is to provide a back feed manifold setup located just downstream of the medical air dryers but upstream of the source valve (or at an auxiliary valve, if available, immediately downstream of the source valve).

The back feed manifold is a fairly simple setup while still allowing for change out of one cylinder at a time. The manifold can be extended to more cylinders if the facility flow is very high, or the duration of shutdown is long enough to require it.

Feel free to contact us if you have any questions about medical air or any other medical gas or vacuum temporary setups. We offer rental manifolds, rental medical vacuum systems and rental medical air systems to help with your next shutdown.